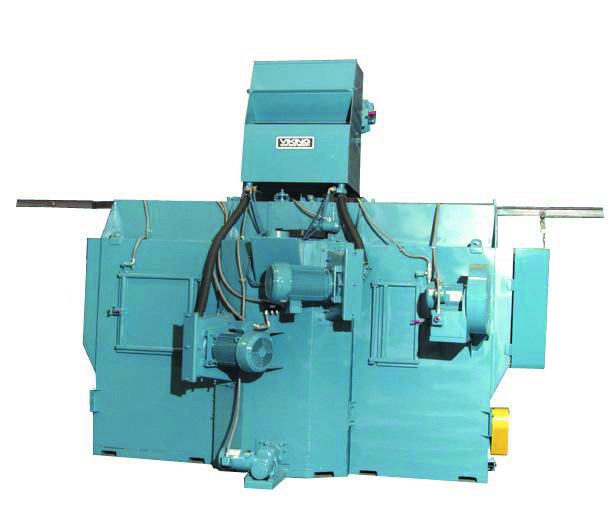

Wheel Blast Equipment

Rodeco can fit you for the right piece of customized equipment to meet your wheel blast equipment needs. Wheel blast equipment offers rapid and heavy-duty blasting to increase productivity. Our wheel blast equipment can handle any material, meet surface specs, and are engineered to finish hard to reach areas.While the capital cost may be higher, most of the time it easily justified by the longer media life and increased production rates. There are many styles of equipment available.

Custom Wheel Blast Equipment

Spinner Hanger

The spinner hanger style of wheel-blast equipment holds a rack of parts from the top and rotates them in front of the blast pattern, and these units can achieve 100% coverage. Units are of many sizes and can blast while the other rack is being loaded or unloade

Monorail Blast

In order to blast steel plates, I beams, or other long parts, the monorail is the return on investment winner. These units provide the most effective method for cleaning a wide variety of parts with variable speeds.

Tumble Blast

Perhaps the most common style of blast-wheel equipment, tumble blasters can handle high volumes of smaller parts that slowly tumble on each other. This is well suited for forgings, fabrications, and heat-treated parts.

By handling parts in bulk, rather than one at a time, labor costs will be lower and your Return on Investment (ROI) will be much higher.

Chain Mesh Belt

When there are high volumes of parts that need 100% coverage, the chain mesh belt can offer high ROI. Rodeco can help you with the ROI analysis.

Table Blast

These provide the most flexible and economical alternatives. Basically, these are large tables (with many diameters offered) that rotate under the blast. These units can hold a single larger part on a rack or a variety of smaller parts.

Purchase The Right Wheel Blast Equipment For Your Job Today.

If you are ready to make a purchase or if you have any questions about our custom wheel blast equipment call us today at