Vibratory Deburring & Burnishing Equipment

Rodeco can fit you for the right piece of customized equipment to meet your vibratory equipment needs… and take you through the entire process, from process development to engineering and setup. From your basic vibe bowl to a sophisticated multi-machine, you’ll get vibratory equipment with an automated process and customized solutions. Experience quality and hit your production targets with Rodeco.

Choose from a wide selection of automated systems. Rodeco has automated systems, ranging in sophistication from standard automation to advanced robotic nozzle, part manipulation and part handling.

Vibratory Deburring & Burnishing Equipment

Rodeco has the capacity to handle a wide range of metal finishing requirements. With over fifteen pieces of finishing equipment, we consistently make metal parts cleaner, brighter, smoother, using advanced manufacturing processes. Rodeco has improved the cost and quality for our customers across the Southeast.

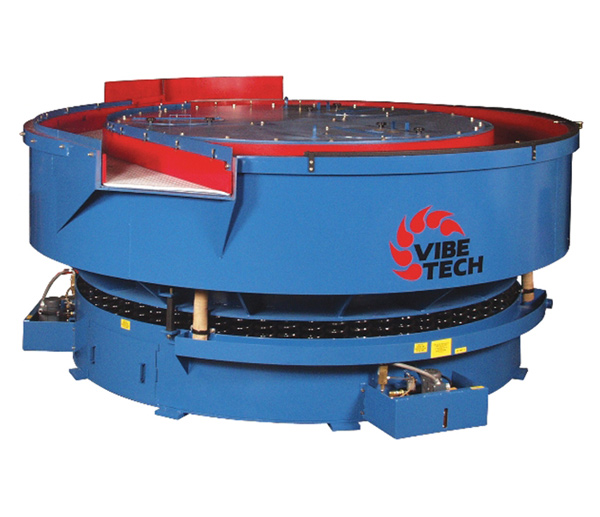

Vibe Tech - Vibratory Bowl Finishing

Standard round vibratory bowl finishers – Vibratory Deburring & Burnishing Equipment by Vibe Tech. Most common and versatile of all vibratory finishing styles of equipment. In Vibe Tech’s line of finishers, two simultaneous actions work in tandem to finish parts. In the first action, the parts tumble within the media in a toroidal motion. In the second action, the finishing machine vibrates at a consistent 1,450 RPM, which scrubs the parts quickly. With that said, the speed also provides a finer, more complete finish than traditional tumblers. With a range of customizable features, our vibratory finishers can be designed to meet any application requirements. Whether you require internal separation, PLC automation, noise covers, pneumatic unload doors, or settling tanks, our finishing equipment is built with experience.

Vibe Tech - Vibratory Tub Finishing

Vibratory Tub finishers (trough vibrators) – Vibratory Deburring & Burnishing equipment by Vibe Tech. Versatile finishing machines for medium to large parts. What that means is, for their capacity, tub finishers provide the maximum channel width. Because of the channel width, the machine allows parts to be easily segregated with customizable, removable compartment dividers. The heavy-duty, interlocking structural design of our tub finishers feature a U-shape design. Also, it is lined with a premium polyurethane lining that is then mounted onto coated coil springs. The drive consists of a premium efficiency motor that powers an offset drive shaft with adjustable weights. Operators can adjust these weights to increase or decrease the aggression of the machine. In combination with the tub finisher’s customizable compartment dividers, this feature ensures a precise surface finish and batch integrity.

Vibe Tech - Inline Finisher

Inline finishers – Vibratory Deburring & Burnishing Equipment by CLM Vibe Tech. Continuous process finishing machines that are designed for high production rates of larger parts. With the ability to eliminate the production bottleneck in the finishing department, they are used heavily in the die cast and CNC machining industries to rapidly deburr and/or deflash parts. Parts are loaded into one end of the machine and go through a finishing process before exiting the opposite end. Afterwards, they are discharged onto a shaker screener to separate the media which is then diverted to a return conveyor that brings a consistent amount back to the beginning. CLM Vibe Tech can work with you to customize our inline finishers to the needs of your production line. Whether you want to send parts into secondary operations like washing or drying, we can tailor our inline finishers to work seamlessly with any of your production process.

Vibe Tech - Long Radius Finisher

Long Radius finisher – Vibratory Deburring & Burnishing Equipment by Vibe Tech. Longer working channels with a larger bowl diameter and a decreasing channel width. Our long radius finishing machines provide a very aggressive action due to an expanded center column that allows for a longer lever arm. This style of finishing machine was specifically designed for steel ball burnishing and continuous operations. Because of their heavy-duty welded construction and proven, oil lubricated drive system, Vibe Tech’s long radius finishing machines are engineered for lasting, long-term performance. Capable of continuous operations ranging from two minutes to fourteen minutes, these machines can be built with custom control panels and tailored to suit your specific application.

Vibe Tech - Cob Dryer

Vibe Tech’s vibratory dryers creates a toroidal motion. Toroidal motion causes a spiraling roll of media parts. Vibratory motion that works together to achieve clean and dry part surfaces without leaving water stains. By utilizing a process channel that is heated from the bottom, our dryers distribute heat evenly. The design of our vibratory dryers also require less floor space than our competitor’s models. With that being said, it also incorporates features such as insulated exterior side walls, that increase operator safety. Because of the Heavy-duty welded construction and flexible design, we can design a dryer that works with your existing finishing machines.

Vibe Tech -Vibratory Combination Finisher/Dryer

Combining the functions of two machines into a single machine saves both space and money. The core of this machine is a vibratory finisher with manual or pneumatic internal separation. This function then feeds the finished parts into an outer channel that dries and polishes them. In this combo machine, we offer both our standard finishers and long radius finishers, which allows you to configure the machine to suit your application. With its efficient use of space, exterior mounted components and custom options, our combination finisher/dryer is ideal for maximizing both floor space and productivity.

Vibe Tech - High Frequency Finisher

Unlike standard vibratory finishers, high frequency finishers generate a unique process that uses less amplitude. In fact, it uses more frequency and a lapping style action. The result is complete part coverage, repeatability, fine polish, superior surface refinement and no part impingement. Parts are fixed within the work chamber. With this gentler process, high frequency finishers are ideal for smoothing high value or sensitive parts. Standard finishers feature a longer working channel.

Vibe Tech - Shaker Screener

Typically used in applications where the entire mass – parts and media – requires separation after being unloaded from a batch finisher, shaker screeners are ideal for applications that require the separation of parts from media or as an offline media classifier. Twin electric vibratory motors create the linear motion and vibration required to transfer the mass forward and generate enough vertical action to aid in separation. In most applications, the media or screened material is dropped to a lower level, moved to the end of the machine and ultimately expelled from a discharge chute where the customer’s media bin or hopper is located.

Vibe Tech - Polyrethane Reliners

Polyurethane reliners refers to the removal of old or worn out linings from your current finishing machine, inspection and repair of structure and replacement of the lining with a new polyurethane material. At VibeTech, we offer a full reline service that covers nearly every make and model of mass finishing equipment. With hundreds of molds at our disposal, we offer fast turnaround times to minimize your production down time. Included with our reline services, we offer replacement of gate assemblies, unload doors, drain assemblies, screen assemblies and equipment repainting. VibeTech has three polyurethane choices in inventory: Cytec Conathane TU-79MF, Cytec Conathane TU-89MF and 95-Durometer hot pour urethane. No matter your needs, whether you’re finishing small, heavy, dull or sharp parts, VibeTech has a lining in stock that suits your process.

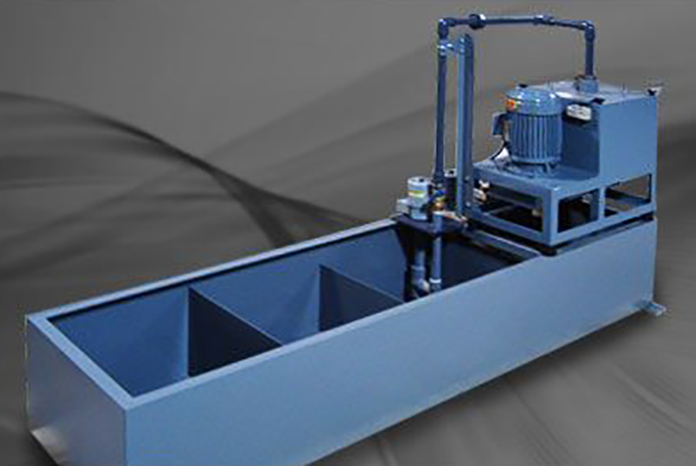

Vibe Tech - Waste Water Treatment

From basic to advanced, equipment options are available to take care of the waste water from mass finishing equipment or aqueous parts washers. Some of the most economical solutions are settling tanks, manual paper bed filters or automatic paper bed filtration. These economical solutions can greatly reduce the amount of ceramic or plastic residue that would go into your building’s waste stream. More advanced options include ultra-filtration, centrifugal separation and flocculation combined with separation. These advanced solutions can clarify the waste water enough that the water can be reused in standard vibratory finishing operations for an extended period of time. This allows you to get more cost savings out of your process and keep overhead down over the life of the project. With water costs rising and an increasingly competitive market out there, investing in waste water treatment is a wise decision for any surface finishing operation.

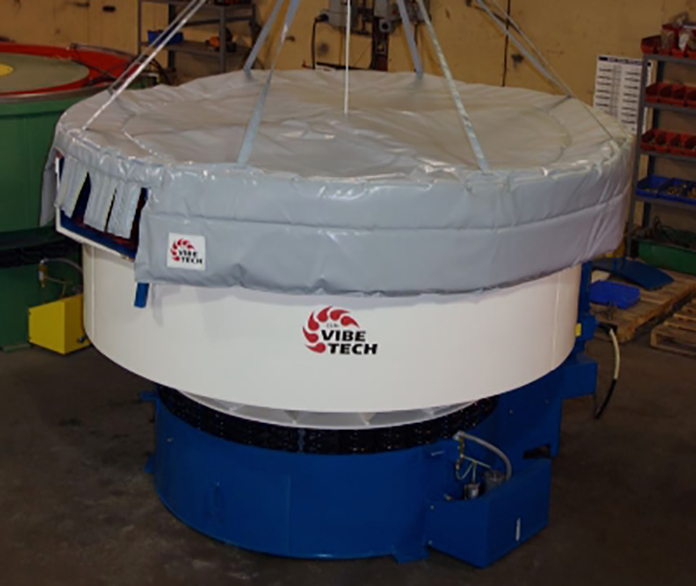

Vibe Tech - Sound Protection

On today’s factory floor, protecting the welfare of your employees is essential to productivity. While mass finishing equipment often creates substantial levels of sound pollution, there is a solution. By adding VibeTech’s sound protection products to your equipment, you can greatly reduce sound pollution and, more importantly, ensure a safe and comfortable environment for your employees. Our most economical solution, a sound cover, is made of heavy-duty vinyl with 1 inch sound abatement foam. The cover is then custom fitted to your machine using any necessary cutouts that are required. For increased durability, we offer rigid sound hoods made of aluminum sheet stock and sound abatement foam. Mounted off of a heavy-duty structural steel base frame, the weight of the hood can be carried by gas shocks or a hydraulically powered cylinder that allows for easy actuation. As with most of our products, VibeTech is capable of customizing and fitting our sound protection products to meet your specific needs.

Let Rodeco help you determine the right vibratory machines and equipment to use for the job by utilizing our process development and lab testing services

For more information on vibratory machines and equipment please call us today